Struggling with CNC Performance in Hot, Dusty Environments?

If your CNC machines are installed in factories exposed to high ambient temperatures or dusty surroundings, chances are you’ve noticed

- Drop in spindle performance

- Unexpected downtime

- Increased wear on machine parts

- Reduced accuracy in machining

This is not a minor inconvenience – it’s a clear sign that your current spindle setup isn’t built for your operating conditions.

Root Cause Many companies operate without air conditioning. During summers or in hot regions, internal shop floor temperatures can exceed 45°C. This heat directly impacts the spindle’s motor and bearing performance, leading to:

- Motor overheating

- Tool misalignment

- Shorter spindle life

- Increased repair frequency

If your current spindle fails to maintain consistent performance in such environments, the solution lies in upgrading to a robust air-cooled spindle system.

Install a High-Performance Air-Cooled Spindle An air-cooled spindle is specifically designed to perform in high-temperature and dusty environments. It uses a built-in fan system to keep the motor and bearings cool during long operations, without requiring any external cooling setup.

Key Benefits of Air-Cooled Spindles:

✅ Built-in fan ensures constant airflow

✅ Zero dependency on external chillers or plumbing

✅ Highly reliable in hot and dusty industrial spaces

✅ Simple installation and low maintenance

✅ Consistent output even in extended-duty cycles

Whether you run a CNC router, milling machine, or engraving system—an air-cooled electro spindle provides the durability and performance needed for tough conditions.

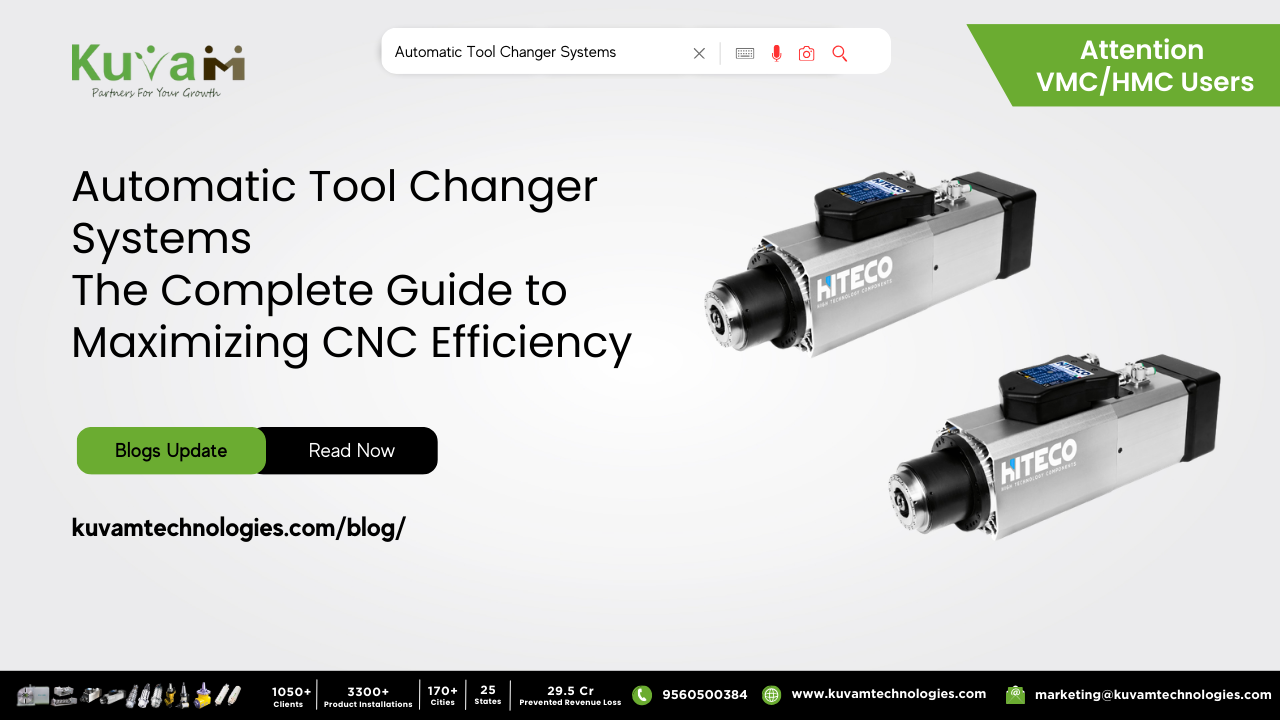

Why Choose Hiteco Air-Cooled Spindles?

At Kuvam Technologies, we supply Hiteco spindles renowned for precision engineering and industrial-grade quality. Hiteco offers both ATC (Automatic Tool Change) and MTC (Manual Tool Change) air-cooled spindles that are widely used across:

- Woodworking

- Aluminium cutting

- Composite machining

- Engraving and routing applications

Choose Based on Your Operation

- MTC Air-Cooled Spindle: Ideal for manual operations or small CNC shops

- ATC Air-Cooled Spindle: Designed for high-speed automated lines needing tool change flexibility

These electro spindles are compact, efficient, and tailored for continuous use—even during peak summer temperatures.

Proven Performance Across Indian Industries

A leading manufacturer in Ahmedabad was struggling with frequent spindle stoppages due to heat. After installing a Hiteco air-cooled ATC spindle, they reported:

- 99% uptime during peak summer

- 25% faster job completion

- Drastic reduction in spindle-related breakdowns

- Improved tool accuracy across long shifts

This transformation didn’t just improve performance—it saved money on repairs, reduced downtime, and improved customer delivery timelines.

Is an Air-Cooled Spindle Right for You?

Yes, if you operate in:

- High-temperature zones

- Open or semi-covered workshops

- Industries like furniture, stone, signboards, doors, panels, or aluminium

- Anywhere dust and heat are part of daily shop floor life

Then an air-cooled electro spindle is the right long-term solution.

If you’re dealing with:

- Frequent spindle overheating

- Dusty conditions

- Need for simple, reliable, low-maintenance solutions

Then it’s time to install a Hiteco air-cooled spindle—available in both ATC spindle and MTC spindle models—to increase reliability, precision, and peace of mind.

Take Action Today

You now have two choices:

❌ Keep working with an underperforming setup and risk downtime during critical jobs.

✅ Upgrade to a high-efficiency air-cooled spindle and ensure smooth, stable machining in any season.

👉 Contact on phone at 9560500384 or email us at marketing@kuvamtechnologies.com Kuvam Technologies today for a free consultation. We’ll help you select the perfect Hiteco electro spindle suited for your machine and production needs.