CNC Rotary Table > Rotary Production System

Download Catalog Now

What is Rotary Production System?

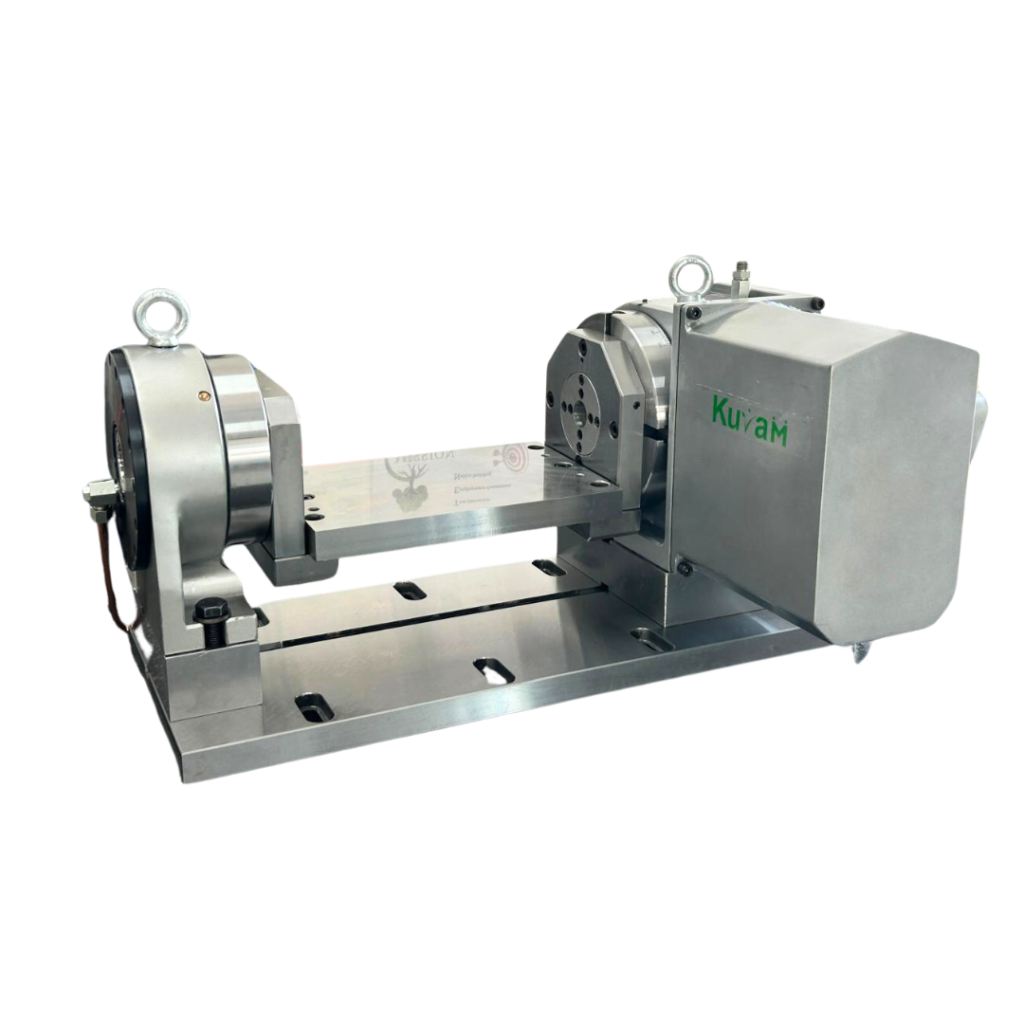

A Rotary Production System is an advanced tool used in machining processes to enhance productivity, precision, and efficiency. It integrates rotary tables with intelligent mechanisms like pneumatic or hydraulic clamping, robust gear systems, and high-performance bearings. These systems are crucial for industries requiring high-speed, multi-directional machining with consistent accuracy.

Why Do We Need a Rotary Production System?

In modern manufacturing, where time and precision are critical, the Rotary Production System addresses key challenges:

- Enhanced Efficiency: It reduces the need for multiple setups by allowing multi-axis machining in one go.

- Increased Accuracy: Ensures precise machining operations, even for complex geometries.

- Time Saving: Accelerates production timelines with automated mechanisms.

- Cost-Effectiveness: Minimizes material wastage and labor costs by reducing errors and rework.

Features of the Rotary Production System

- Pneumatic / Hydraulic Clamping: Ensures firm and stable workpiece holding for vibration-free operations, leading to higher precision.

- Pre-Loaded Axial Radial Roller Bearing: Supports heavy loads and ensures smooth, precise rotation with minimal wear.

- Gear Mechanism (Motor to Worm Shaft): A robust transmission system providing consistent and efficient motion.

- Dual Lead Worm Gear Set: Offers high torque transmission and enhances positional accuracy.

- Higher Clamping Torque: Enables machining of heavy and large workpieces without slippage or misalignment.

- Hydraulic Braking Mechanism (Rotary & Faceplate): Provides secure stopping and stability during operations, increasing reliability.

- Tailstock Support: Ensures stability for long or heavy workpieces, enhancing operational versatility.

| Model | KX4RPS215 | KX4RPS265 | KX4RPS335 | |

|---|---|---|---|---|

| Table Diameter(mm) – Rotary Table | Ø215 | Ø265 | Ø335 | |

| Table Diameter(mm) – Face Plate Tail Support | Ø180 | Ø180 | Ø225 | |

| Diameter of Center bore(mm) | Ø60H7 | Ø60H7 | Ø100H7 | |

| Tenon Slot size(mm) | 14H7 | 18H7 | 18H7 | |

| Diameter of Through Hole(mm) | Ø50 | Ø50 | Ø75 | |

| Table Center Height(mm) | 145 | 170 | 215 | |

| Tenon Slot Size(mm) | 18H7 | 18H7 | 18H7 | |

| Speed reduction ratio– Rotary Table | 1:90 | 1:120 | 1:144 |

Order CNC Rotary Production System

Get Professional Servicing & Repairs

Need Advice talk to our Experts

Order CNC Rotary Production System

Get Professional Servicing & Repairs

Need Advice talk to our Experts

Clients

0 +

Product Installation

0 +

Cities

0 +

States

0 +

Revenue Loss prevented

0 Cr.

Working for some of the leading companies...

Boost Your Machining Performance and Output with us in Just a little investment enquire now for more details

- Hours: Mon-Sat 10:00AM - 07:00PM

- Phone: +919560500384

- Email: marketing@kuvamtechnologies.com