Introduction to Rotary Tables for CNC VMC Machines

Rotary tables are essential in modern machining, particularly for CNC VMC (Vertical Machining Center) machines. These devices allow for precise positioning and rotation of the workpiece, enabling complex machining tasks to be performed with high accuracy. In this comprehensive guide, we’ll explore everything you need to know about rotary tables for CNC VMC machines, from their benefits and types to installation and maintenance tips.

What is a Rotary Table?

A rotary table is a precision work positioning device used in metalworking. It enables the operator to rotate the workpiece around a fixed axis, allowing for intricate machining operations such as milling, drilling, and cutting. Rotary tables can be manually operated or controlled via CNC systems, providing versatility in various machining applications.

Benefits of Using a Rotary Table for CNC VMC Machines

Enhanced Precision and Accuracy

One of the primary advantages of using a rotary table for CNC VMC machines is the enhanced precision and accuracy it provides. The rotary table allows for precise angular positioning, making it possible to machine complex geometries with high precision.

Increased Machining Flexibility

With a rotary table, CNC VMC machines can perform a wider range of operations. This flexibility is particularly beneficial for industries that require the production of complex parts, such as aerospace, automotive, and medical device manufacturing.

Improved Efficiency and Productivity

By incorporating a rotary table into a CNC VMC machine setup, operators can reduce setup times and increase overall productivity. The ability to machine multiple faces of a workpiece in a single setup minimizes downtime and enhances workflow efficiency.

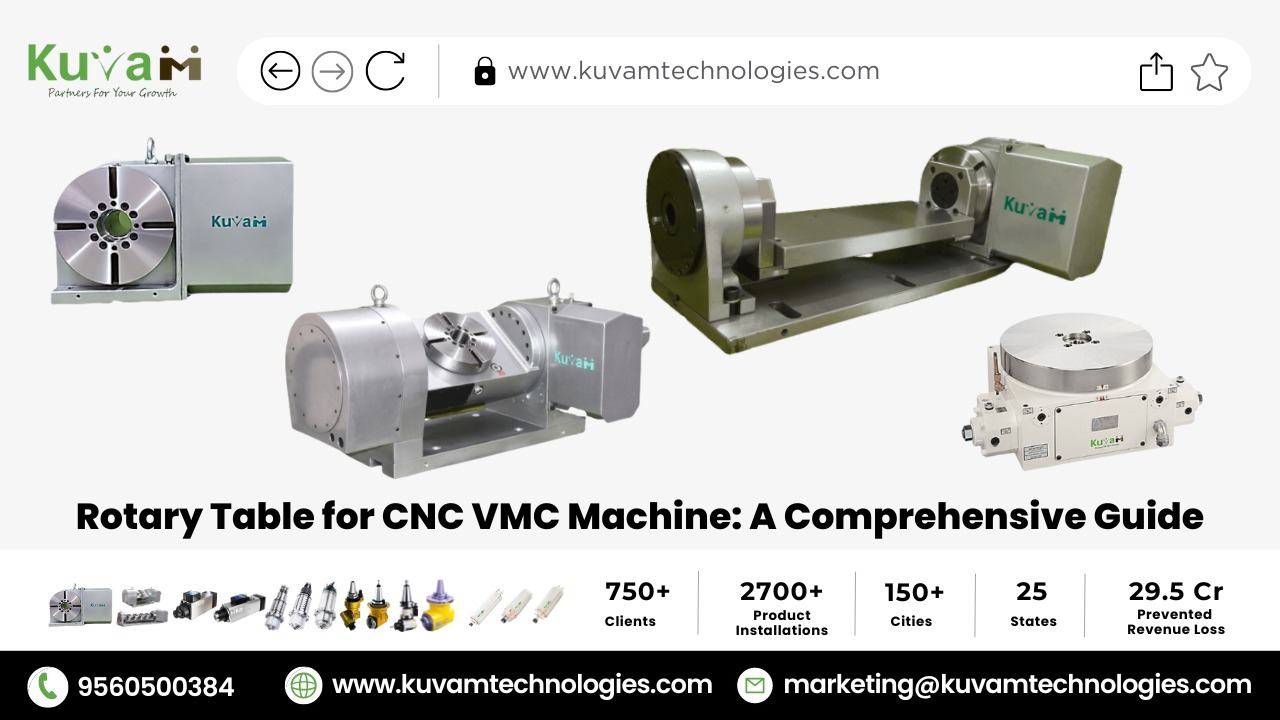

Types of Rotary Tables for CNC VMC Machines

- 4th Axis CNC Rotary Table

A 4th Axis CNC Rotary Table adds a new dimension to the machining capabilities of CNC VMC machines. This type of rotary table allows for the rotation of the workpiece around a horizontal axis, enabling complex machining operations that require multi-sided machining.

- Tilting Rotary Table

A Tilting Rotary Table offers additional flexibility by allowing the workpiece to be tilted at various angles. This feature is particularly useful for machining inclined surfaces and creating complex geometries that are not possible with a standard rotary table.

- Rotary Production System

A Rotary Production System is designed for high-volume production environments. This type of rotary table integrates multiple workstations, allowing for continuous machining operations. It enhances productivity and efficiency by reducing setup times and facilitating automated workflows.

- Hydraulic Indexing Table

A Hydraulic Indexing Table uses hydraulic power to rotate and position the workpiece accurately. This type of rotary table is known for its high torque capabilities and precise indexing, making it ideal for heavy-duty machining operations.

How to Choose the Right Rotary Table for Your CNC VMC Machine

- Consider the Workpiece Size and Weight

When selecting a rotary table for your CNC VMC machine, it’s essential to consider the size and weight of the workpieces you will be machining. Ensure that the rotary table can handle the maximum weight and dimensions of your workpieces without compromising accuracy.

- Determine the Required Precision

The required precision of your machining operations will influence your choice of rotary table. CNC rotary tables generally offer higher precision compared to manual ones. Consider the tolerance levels and accuracy requirements of your projects when making your selection.

- Evaluate the Available Space

Space constraints in your workshop or manufacturing facility should also be considered. Ensure that the rotary table you choose fits within the available space and can be easily integrated with your existing CNC VMC machine setup.

Installation and Setup of a Rotary Table for CNC VMC Machines

- Preparing the CNC VMC Machine

Before installing the rotary table, ensure that your CNC VMC machine is clean and free of debris. Check for any obstructions that might interfere with the installation process.

- Mounting the Rotary Table

Securely mount the rotary table onto the CNC VMC machine’s work surface. Ensure that it is properly aligned and fastened to prevent any movement during operation. Use appropriate mounting hardware and follow the manufacturer’s guidelines.

- Integrating with the CNC Control System

If you are using a CNC rotary table, connect it to the CNC VMC machine’s control system. Follow the manufacturer’s instructions for wiring and configuration to ensure seamless communication between the rotary table and the machine.

Maintenance Tips for Rotary Tables on CNC VMC Machines

- Regular Cleaning

Keep the rotary table clean and free of debris to ensure smooth operation. Regularly remove chips and other contaminants that can accumulate during machining.

- Lubrication

Proper lubrication is essential for maintaining the performance and longevity of the rotary table. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricants.

- Inspection and Calibration

Periodically inspect the rotary table for signs of wear and tear. Check for any loose components and ensure that the table is properly calibrated. Regular maintenance checks will help prevent unexpected breakdowns and ensure optimal performance.

Contact us For more information, please get in touch with us at marketing@kuvamtechnologies.com or call us at 9560500384. We look forward to helping you achieve greater precision and efficiency in your work.

Experience the future of machining with Kuvam Technologies. I appreciate your interest, and we look forward to supporting your journey toward excellence.