Air Cooled SpindleBlogCNC Electro SpindleHiteco SpindleKuvam SpindleMilling SpindleSpindleSpindle MotorWater Cooled Spindle

How to Select the Right CNC Spindle: Key Differences for Woodworking, Stone Carving, and Die Engraving

If you’re working with a CNC machine, you know the spindle is a very big deal. It’s the part that holds the cutter and makes it spin, and frankly, it decides how good your final product will be. But with...

Air Cooled SpindleArticlesBlogCNC Electro SpindleCNC MachiningDirect Driven SpindlesHiteco SpindleKuvam SpindleMilling SpindleMilling SpindleSpindleSpindle MotorWater Cooled Spindle

Why Choose a High-Speed CNC Spindle? Key Benefits Explained

Hey there, CNC enthusiasts! If you’re like me, you probably geek out over anything that makes your shop run smoother, faster, and just plain better. That’s where the high-speed CNC spindle comes in—it’s like the superhero of your CNC machine....

Overheating in High Ambient Temperatures? Choose Air-Cooled Spindle

Struggling with CNC Performance in Hot, Dusty Environments? If your CNC machines are installed in factories exposed to high ambient temperatures or dusty surroundings, chances are you’ve noticed Drop in spindle performance Unexpected downtime Increased wear on machine parts Reduced...

Air Cooled SpindleBlogHiteco SpindleKuvam SpindleMilling SpindleMilling SpindleSpindleSpindle MotorWater Cooled Spindle

The Power of High-Frequency Spindles in Modern Machining

The Power of High-Frequency Spindles in Modern Machining In the world of CNC machining, high-frequency spindles have revolutionized precision cutting, engraving, and milling processes. These spindles, designed for high-speed applications, offer unmatched efficiency, accuracy, and surface quality. Whether in woodworking,...

Why Spindle Chillers Are Essential for CNC Machines: Benefits, Types, and Tips

When running a CNC machine, the spindle is one of the most important parts. It drives the cutting tools that shape and create your products. Whether you use a belt-driven spindle or a direct-driven spindle, keeping it cool is key...

Air Cooled SpindleBlogCNC Electro SpindleHiteco SpindleKuvam SpindleMilling SpindleSpindle MotorWater Cooled Spindle

CNC Router Spindles: Why They Matter and How to Choose the Right One

CNC Router Spindles: Why They Matter and How to Choose the Right One The spindle is crucial for a CNC router. It’s like the machine’s “engine.” It powers the cutting tool for smooth, precise cuts. Whether for detailed designs or...

How to Increase Production with VMC: Step-by-Step Guide

At Kuvam Technologies, founded by Sreenivasulu Patti, we have been committed to delivering true service since our inception in 2010. We specialize in CNC Rotary Tables, Spindles, and Angular Heads, empowering manufacturing success across India. With 850 satisfied clients, 2800...

Air Cooled Spindle: Your Guide to Efficient and Reliable Spindle Cooling

Introduction Are you in the machining industry and looking for an efficient, reliable, and cost-effective solution for spindle cooling? Look no further! In this post, we’ll guide you through the benefits and setup process of air cooled spindles, a vital...

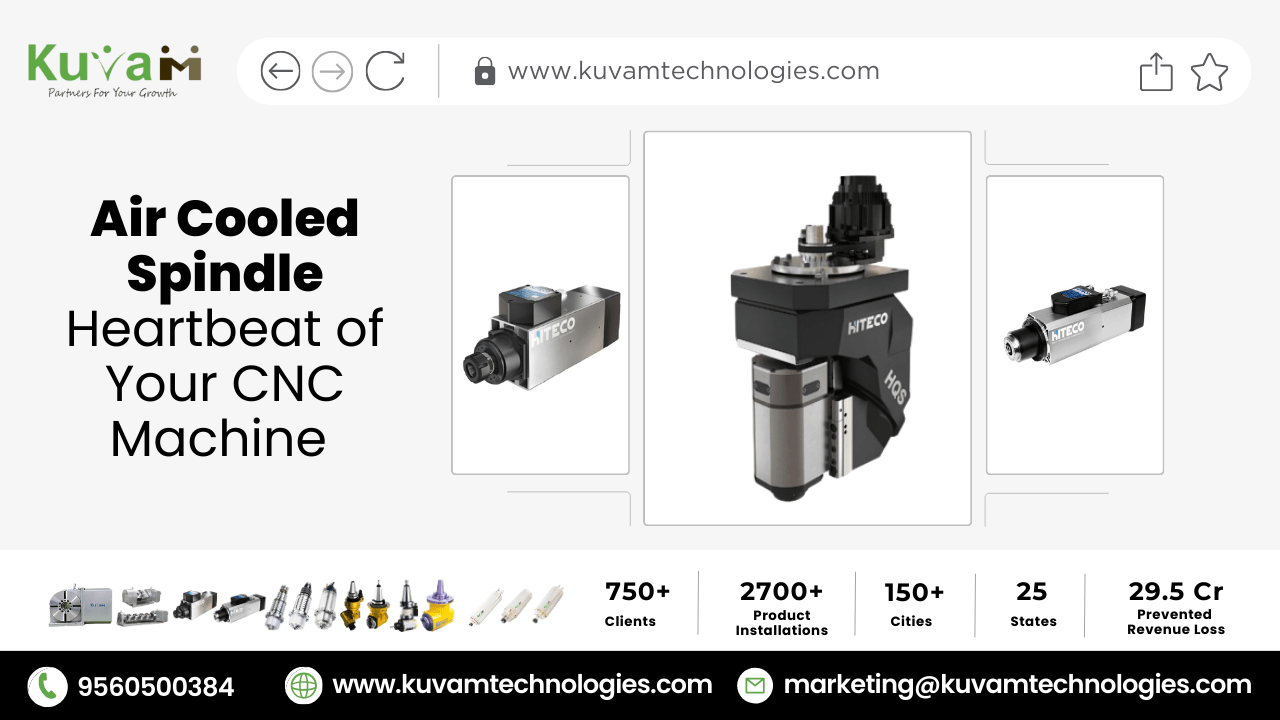

Air Cooled Spindle – Heartbeat of Your CNC Machine

One of the most critical components of CNC (Computer Numerical Control) machines is the spindle. The spindle is responsible for holding and rotating the cutting tool, which is essential for machining operations. Among the various types of spindles, the air...

Kuvam High Precision CNC Router Spindles – The Heart of Precision

Kuvam has specialized in high-precision machine spindles for various machine types as milling, turning, mill-turn, multi-spindle, tapping, and grinding. It is the component responsible for rotating the cutting tool and performing the actual machining operations. One type of spindle that...