How to Increase Production with VMC: Step-by-Step Guide

At Kuvam Technologies, founded by Sreenivasulu Patti, we have been committed to delivering true service since our inception in 2010. We specialize in CNC Rotary Tables, Spindles, and Angular Heads, empowering manufacturing success across India. With 850 satisfied clients, 2800...

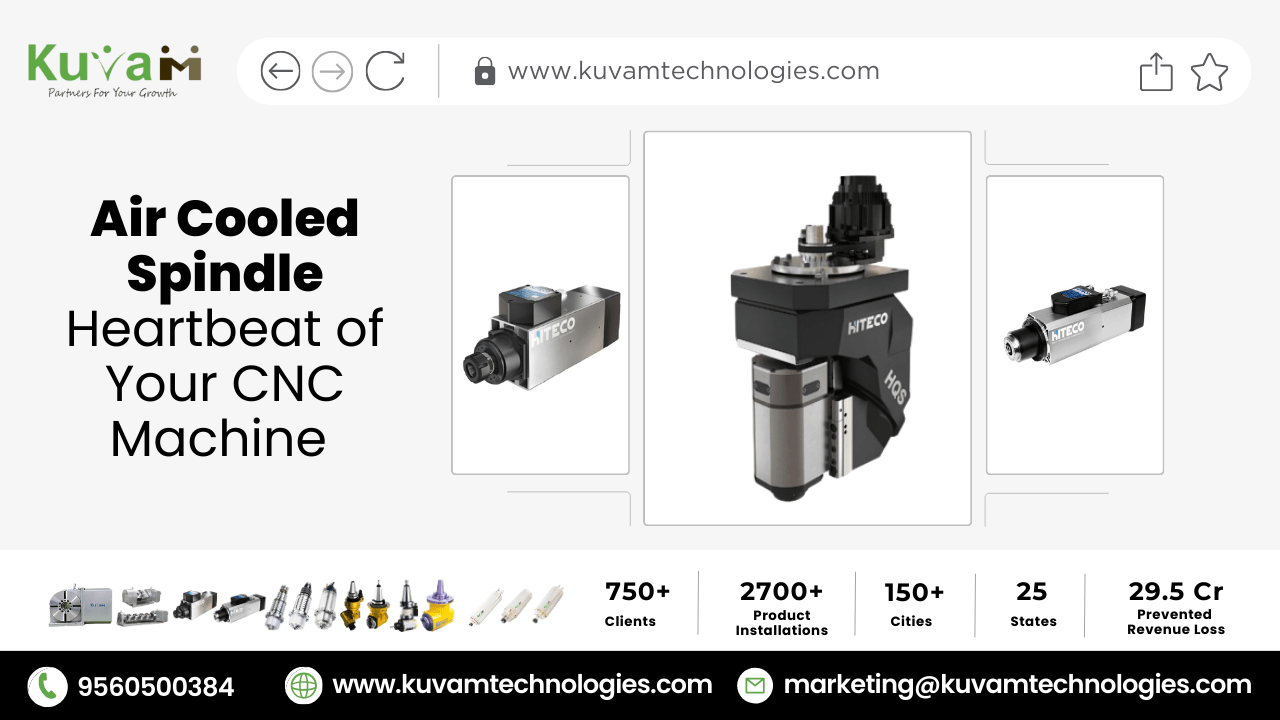

Air Cooled Spindle – Heartbeat of Your CNC Machine

One of the most critical components of CNC (Computer Numerical Control) machines is the spindle. The spindle is responsible for holding and rotating the cutting tool, which is essential for machining operations. Among the various types of spindles, the air...

Top 10 Benefits of Using a Water Cooled Spindle

In CNC machining, picking the right spindle is key for accuracy, efficiency, and durability. Water-cooled spindles stand out for their superior cooling, enhancing performance and lifespan. This article will outline the top 10 benefits of water-cooled spindles, proving they’re ideal...

Kuvam High Precision CNC Router Spindles – The Heart of Precision

Kuvam has specialized in high-precision machine spindles for various machine types as milling, turning, mill-turn, multi-spindle, tapping, and grinding. It is the component responsible for rotating the cutting tool and performing the actual machining operations. One type of spindle that...

Are you facing a runout problem in spindle?

If you’re facing a runout problem in a spindle, where the spindle exhibits excessive radial or axial movement, it can negatively impact machining accuracy and surface finish. Here are some steps you can take to address spindle runout: Check...

Do you know common problems associated with water-cooled spindles?

Coolant Leakage Have you experienced coolant leakage from the water-cooled spindle? Solution: Check and tighten hose connections, inspect hoses for damage, and replace seals if necessary. Regularly monitor coolant levels. Overheating Do you notice the water-cooled spindle overheating during operation?...

What are common problems associated with air-cooled spindles?

Overheating: Problem: The spindle gets too hot during operation. Solution: Check and ensure proper functioning of the cooling system (fan), clean cooling fins regularly, and optimize cutting parameters to reduce heat generation. Inadequate Cooling: Problem: Insufficient cooling affecting spindle performance....

How to prevent pre-mature-failure of bearings in spindle?

Pre-mature failure of bearing in Machine Spindles is due to various reasons: Unbalanced Tool Holder, collet, and tools Entry of Dust Particles/Contamination Wrong usage Insufficient cooling Insufficient Lubrication 1 . Unbalanced Tool Holder, collets, and Cutting...