In CNC machining, picking the right spindle is key for accuracy, efficiency, and durability. Water-cooled spindles stand out for their superior cooling, enhancing performance and lifespan. This article will outline the top 10 benefits of water-cooled spindles, proving they’re ideal for your machining needs.

Table of Contents

What is a water-cooled spindle?

Superior Cooling Efficiency

Enhanced Performance

Increased Durability

Reduced Noise Levels

Consistent Operating Temperatures

Improved Precision

Energy Efficiency

Versatility in Applications

Environmental Benefits

Conclusion

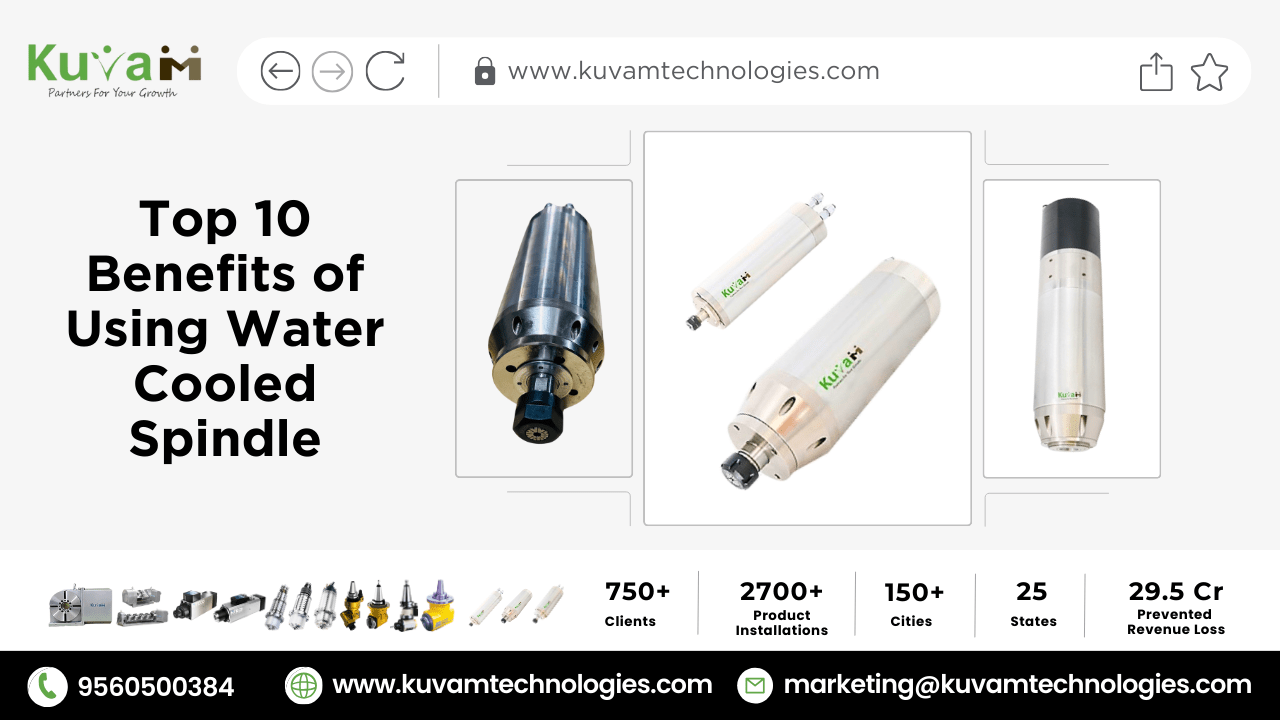

What is a water-cooled spindle?

A water-cooled spindle uses circulating water to cool it. It dissipates heat generated during operation. This cooling method keeps the spindle at optimal temperatures. It boosts its performance and lifespan. CNC machines commonly use water-cooled spindles for high-precision, continuous work.

Superior Cooling Efficiency

Effective Heat Dissipation

A water-cooled spindle’s biggest advantage is its cooling efficiency. Water has a high thermal conductivity, making it an excellent medium for transferring heat away from the spindle. This heat dissipation keeps the spindle cool, even during long, high-speed runs.

Prevention of Overheating

A water-cooled spindle prevents overheating by keeping a stable temperature. Overheating can damage the spindle and harm the workpiece’s quality. This reliability is crucial for maintaining consistent performance in demanding machining tasks.

Enhanced Performance

High-Speed Operation

A water-cooled spindle can operate at higher speeds compared to air-cooled alternatives. The efficient cooling system prevents the spindle from overheating at high RPMs. This boosts productivity and speeds up machining.

Better Cutting Performance

The enhanced cooling provided by a water-cooled spindle contributes to better cutting performance. The spindle can easily handle tougher cuts and demanding materials. It delivers superior finishes and higher precision.

Increased Durability

Extended Lifespan

Water-cooled spindles are known for their durability and long lifespan. The efficient cooling system reduces heat on the spindle. It minimizes wear and tear. This longevity makes water-cooled spindles a cost-effective investment in the long run.

Lower Maintenance Requirements

Water-cooled spindles have less thermal stress. So, they need less maintenance than other spindles. This reliability means less downtime and lower maintenance costs, enhancing overall productivity.

Reduced Noise Levels

Quieter Operation

Water-cooled spindles are generally quieter than their air-cooled counterparts. The absence of fans and the efficient cooling process result in a significantly lower noise output. This quieter operation helps create a more pleasant, comfortable work environment.

Enhanced Workplace Comfort

The lower noise levels help both operators and the workplace. They create a more comfortable and productive environment. Less noise pollution can reduce fatigue and improve focus. This leads to better work.

Consistent Operating Temperatures

Stable Temperature Control

A water-cooled spindle maintains consistent operating temperatures, which is crucial for precision machining. The stable temperature control keeps the spindle at peak performance, no matter the workload or conditions.

Reduced Thermal Expansion

By keeping the spindle at a constant temperature, thermal expansion is minimized. This stability is vital for tight tolerances and high precision in your machining projects.

Improved Precision

Enhanced Accuracy

A water-cooled spindle has stable operating temperatures and efficient cooling. This improves machining accuracy. The spindle can maintain precise movements and performance. This is critical for high-quality outputs.

Superior Surface Finish

A water-cooled spindle has better precision and cutting. It gives superior surface finishes. A water-cooled spindle can deliver smooth, high-quality finishes on your workpieces. This is true for metals, plastics, and composites.

Energy Efficiency

Optimized Power Usage

Despite their powerful performance, water-cooled spindles are often more energy-efficient than air-cooled models. Water’s efficient heat transfer cuts the need for extra cooling. This optimizes energy use.

Lower Operational Costs

The energy efficiency of water-cooled spindles translates into lower operational costs. Reducing energy use saves on electricity bills. It won’t hurt performance or productivity.

Versatility in Applications

Wide Range of Uses

Water-cooled spindles are versatile. They work in many fields, from woodworking and metalworking to plastics and composites. They are reliable and precise. So, they suit both small and industrial machining tasks.

Compatibility with Various CNC Machines

These spindles are compatible with various CNC machines, making them a flexible choice for different setups. A water-cooled spindle can integrate into your workflow. It works whether you upgrade an existing machine or build a new one.

Environmental Benefits

Reduced Heat Emission

The efficient cooling system of a water-cooled spindle reduces heat emission into the environment. This can make workspaces cooler and more comfortable. It can also lower air conditioning costs in controlled environments.

Water Recycling Options

Many water-cooled spindle systems offer options for water recycling, minimizing water waste. A closed-loop system can recirculate the same water. It makes the cooling process more sustainable and eco-friendly.

Conclusion

A water-cooled spindle has many advantages. It is a great choice for high-precision, demanding CNC machining. Water-cooled spindles deliver high-quality results. They cool better, perform better, last longer, and are eco-friendly. A water-cooled spindle can improve precision and lower costs. It also makes machining more sustainable.

Talk to an expert now @ 9560500384